More about cleanroom classification:

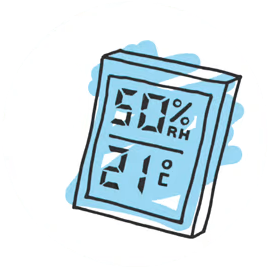

Cleanrooms are designated as controlled environments in which the concentration of airborne particles is carefully regulated. Their construction and operation are tailored to minimise the introduction, generation, and retention of particles and microbes within the space, while also controlling other relevant parameters like temperature, humidity, and pressure.

Impact of Particle Size on Classification

The cleanliness level, or ISO Class, of a cleanroom is determined by the concentration of airborne particles larger than 0.5µm per cubic metre. When a cleanroom is designed and built in a pristine environment using non-particulating materials, its cleanliness is primarily influenced by the airflow.

For instance, if a customer requires a cleanroom with fewer than 100 particles per square metre, they may opt for an ISO 5 cleanroom. However, the size of the particles matters significantly. A particle of 0.5 microns has different implications than a particle of 5 microns. Mistakenly assuming a particle to be 0.5 microns when it is actually 5 microns can lead to an incorrect classification. Instead of an ISO 5 cleanroom, it would be designated as an ISO 8 cleanroom from a cleanroom classification perspective.

Relationship between Contamination and Cleanroom Classification

Modular cleanrooms must be designed, constructed, and operated according to the cleanliness classification defined in ISO 14644-1.

The required level of cleanliness for a cleanroom depends on the specific tasks performed within it. Products that are highly susceptible to contamination necessitate higher cleanliness standards. Once a classification is determined, the cleanroom must be maintained to meet the specifications for:

- Cleanliness

- Temperature

- Humidity

- Pressure

- Number of air changes per hour

- Flow rate

Cleanroom ISO Classification

Cleanrooms are classified into ISO Class 1 (the cleanest) through ISO Class 9, with lower ISO ratings indicating a cleaner environment.

For example, an ISO Class 6 cleanroom is rated at 35,200 particles per cubic metre, where the concentration of particles larger than 0.5 microns must not exceed 35,200 per cubic metre.